Shanghai ChenFei Machinery Technology Co.,Ltd

Shanghai Chenfei Machinery Technology Co.,Ltd

is a leading enterprise which is focus on manufacturing the healthy

food processing machine. We provide full service of integrating

technical developing.R&D, manufacturing, installation debugging

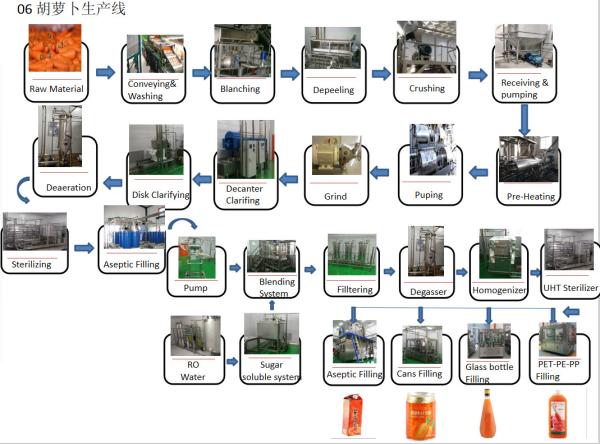

and training for the turnkey production line for different NFC

fruit and vegetable juice, fruit jam and powder,dairy product,

protein beverage, tea drink, function n beverage, preserved fruit,

fruit wine and vinegar, enzyme products, probiotics and some other

liquid & solid product. Chenfei also introduced the German and

Italian advanced technique and have been engaged in developing new

processing machines according to the value of different

agricultural products.Chenfei's coretechnology and production

capacity is in the leading level and has won consistent high praise

from the domestic and oversea customers; Chenfei took part in the

food industry event and exhibitions all over the worid more than 50

times successfully in last few years 60% of our machines be sold

abroad and our customers are in Europe, American, Southest Asia,

Japan, Korea, Africa, Middle Eas and South America.

ChenFei recruits professional and technical

personnel from the industry. Core technical team consists of five

R&D, engineering and technical persons, who graduated from Hua

Zhong Agricultural University, Yangtze university, university of

Shanghai for Science and Technology and other professional

institutes respectively. Technical team continues to grow, which

will contribute to the strength and lasting vitality for solutions

and sustainable development of innovation and will continue to

improve customer value, enhance customer competitiveness.

The company is committed to build the customer

partnershipsmeet and exceed the customers' expectations, and

continuously improving the customers' core competitiveness. Chenfei

is also committed to grow together with the empolyees, realizevalue

and share develoment results.